Description

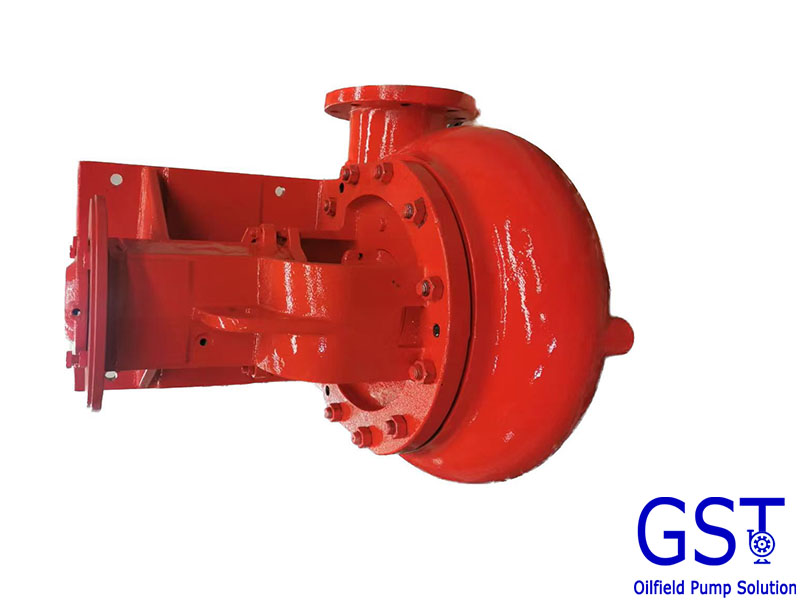

A centrifugal mud pump is a powerful and versatile pumping solution designed to handle abrasive drilling fluids, slurries, and muds in drilling operations. Utilizing centrifugal force, these pumps efficiently transport fluids through pipelines, providing essential circulation and pressure control during drilling processes. We select the high-quality materials and adopt stringent craftsmanship procedures to ensure the high standards of the product. Our mud pump adopts single stage axial suction structure. Material of fluid end parts take wear resistant ductile iron, also available with high chrome corrosive and abrasive resistant material. Our thick, high strength concentric casing provides extended service life over conventional volute designs. The concentric casing design reduces turbulence and abrasive wear to the minimal level.

Features

- Long life: Highly wear resistant ductile iron for fluid end parts.

- Wider open impeller increases flow and longer bearing life.

- Long life mechanical seal for near zero leakage.

- Grease lubrication for bearings.

Application

- Feed pump for solids control equipment

- Mixing pump for jet mud mixer

- Supercharging pump

- Trip pump

Specifications (based upon 20℃ clear water)

|

Model

|

Impeller

Diameter

|

Capacity,

m³/h(gpm)

|

Head,

m(feet)

|

Speed, rpm

|

Efficiency

|

Power, kW

|

NPSHR

m(feet)

|

|

50HZ

|

60HZ

|

%

|

Shaft power

|

Motor power

|

|

SBM8×6

|

12-1/2”

|

255 (1123)

|

32 (105)

|

1450

|

1750

|

67

|

33.2

|

75

|

2.5 (8.2)

|

|

11-1/2”

|

250 (1101)

|

24 (78.7)

|

1450

|

1750

|

63

|

25.9

|

55

|

2.7 (8.8)

|

|

11”

|

245 (1079)

|

20 (65.6)

|

1450

|

1750

|

62

|

21.5

|

45

|

2.7 (8.8)

|

|

10”

|

210 (925)

|

17 (55.8)

|

1450

|

1750

|

70

|

13.9

|

30

|

3.0 (9.8)

|

|

SBM6×5

|

12-1/2”

|

200 (881)

|

34 (111)

|

1450

|

1750

|

65

|

28.5

|

55

|

3.2 (10.5)

|

|

12”

|

195 (859)

|

31 (102)

|

1450

|

1750

|

68

|

24.2

|

45

|

3.0 (9.8)

|

|

11”

|

190 (837)

|

24 (78.7)

|

1450

|

1750

|

70

|

17.7

|

37

|

3.5 (11.5)

|

|

SBM5×4

|

12”

|

110 (484)

|

32 (105)

|

1450

|

1750

|

65

|

14.7

|

30

|

3.5 (11.5)

|

|

11”

|

105 (462)

|

27 (88.6)

|

1450

|

1750

|

68

|

11.4

|

22

|

4.0 (13.1)

|

|

10”

|

100 (440)

|

21 (68.9)

|

1450

|

1750

|

68

|

8.4

|

18.5

|

4.2 (13.8)

|

|

9-1/2”

|

95 (418)

|

17 (55.8)

|

1450

|

1750

|

68

|

6.5

|

15

|

4.2 (13.8)

|

|

SBM4×3

|

11-1/2”

|

90 (396)

|

30 (98.4)

|

1450

|

1750

|

65

|

11.3

|

22

|

3.6 (11.8)

|

|

11”

|

85 (374)

|

27 (88.6)

|

1450

|

1750

|

65

|

9.6

|

18.5

|

3.5 (11.5)

|

|

10”

|

80 (352)

|

21 (68.9)

|

1450

|

1750

|

66

|

6.9

|

15

|

3.5 (11.5)

|

|

9”

|

70 (308)

|

16 (52.5)

|

1450

|

1750

|

66

|

4.6

|

11

|

3.5 (11.5)

|

|

SBM3×2

|

11-1/2”

|

60 (264)

|

27 (88.6)

|

1450

|

1750

|

56

|

7.8

|

15

|

2.5 (8.2)

|

|

11”

|

50 (220)

|

25 (82)

|

1450

|

1750

|

56

|

6.1

|

11

|

2.5 (8.2)

|

|

10”

|

45 (198)

|

21 (68.9)

|

1450

|

1750

|

60

|

4.3

|

7.5

|

2.3 (7.6)

|

|

9”

|

40 (176)

|

16 (52.5)

|

1450

|

1750

|

60

|

2.9

|

5.5

|

2.1 (6.9)

|

Packaging & Shipment

Packaging type: Export plywood box

Exporting port: Tianjin, Shanghai

FAQ

1. Who are you?

Tianjin Geostar Petroleum Equipment Co., Ltd. are integrated oilfield pump solution provider. We produce GST brand centrifugal pump and supply RG brand F series drilling mud pump, parts, plunger pump etc.

2. Why should we buy from you?

a. Competitive price

b. Quick delivery

c. Worry free after-sales service. Refund or sending new goods if quality issues can't be resolved by after-sales service.

3. Is after-sale service available to your products?

Yes, we have professional after-sale service team which will offer you the site commissioning service. Engineers are available to be abroad for service.

4. What is your warranty policy?

We offer 12 months limited warranty for complete set of equipment or machinery.

5. What is the delivery time for your product?

Generally, ready stock for commonly used parts, mud pump unit and complete equipment depends upon technical configuration.

Language :

Language : English

English Русский

Русский عربي

عربي

GET A QUOTE

GET A QUOTE

IPv6 network supported

IPv6 network supported